Новые решения

The design team of the Belpromproekt Institute is in constant creative search, the result of which are new design solutions. The use of non-standard and innovative solutions increases the operational characteristics of facilities, reduces construction time, and, often, is the only way to implement technical specifications.

This section provides examples of new solutions implemented by the Belpromproject Institute::

- Soil fixing technology ;

- The use of steel-reinforced concrete structures in the construction of a newsprint plant in the city of Shklov;

- Development of ice cover design ;

- Application of a roof from sprayed polyurethane foam;

- The use of a number of new design solutions in residential construction .

Soil fixing technology

During the construction of the Europe Hotel in the historical center of Minsk, it was required to perform soil reinforcement under the foundation of the Academy of Music adjacent to the hotel foundation pit. With the participation of the Department of “Geotechnics and Ecology in Construction” of BNTU, the institute’s designers developed and applied the design of screw fixation of soils with a difference of 5 m in order to reduce lateral pressure on the tongue and groove of the foundation pit of bored piles.

The use of steel-reinforced concrete structures in the construction of a newsprint factory in the city of Shklov

In 2006-2007 As part of the construction of a newsprint factory in Shklov, the Belpromproject Design Institute, together with the BNTU, designed the floors of the production buildings. The total area of the floors was 4800 sq.m.

The said overlappings had a number of features, namely:

- Non-standard step of the columns, which did not allow the use of standard reinforced concrete crossbars;

- Large loads on the floor, so in accordance with the design assignment, the useful standard load on the floor was 2500 kg / sq.m .;

- Limited ceiling height, which allows to increase the useful volume of the premises;

- Operation of the ceiling in a highly aggressive environment.

In addition, the following requirements were imposed on the ceilings:

- Low rigidity;

- Manufacturability;

- Reliability and safety.

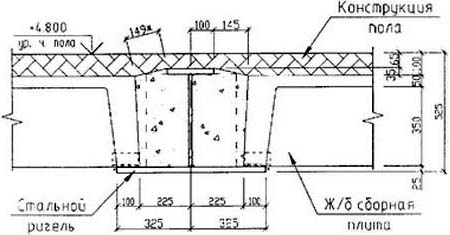

Based on these requirements, it was decided to use steel-reinforced concrete structures. The steel-reinforced concrete structure consists of a steel composite crossbar of an asymmetric I-section and precast reinforced concrete ribbed plates laid on the crossbar (see figure). The main feature of the steel-reinforced concrete structure is the joint work of the crossbar and reinforced concrete slabs, which makes their use especially effective. The joint work of steel and reinforced concrete parts is achieved by constructive measures: monolithic interfacing of reinforced concrete slabs with a crossbar, installation of stops (ordinary and interplate), welding of embedded parts of plates to steel crossbars. Precast concrete slabs of the standard series 1.442.1-1 / 87 were used to simplify the construction of the floor.

The calculation of steel-reinforced concrete structures also has a number of features associated with the joint work of steel and concrete. It is known that the “manual” calculation of such structures is largely time-consuming, and therefore, the FPLASTIC computer program was used for the calculation developed by the staff of the department «Metal and wooden structures» under the guidance of Professor Martynov Yu.S. The program is based on its own algorithm that implements the “deformation model” generalized to steel-reinforced concrete structures. All calculations comply with current regulatory documents and take into account physical non-linearity. The nonlinear work of the material was taken into account using real deformation diagrams: for steel, Prandtl diagrams, for concrete, a parabolic-linear diagram. The FPLASTIC program has its own interface integrated into the FEMAP pre-processor, which provides additional convenience in inputting the input data and analyzing the results.

Development of ice cover design

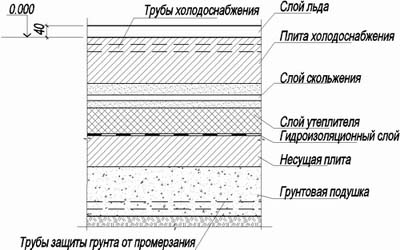

The ice field is a complex multi-layer structure, an integral element in the design of indoor skating rinks, sports palaces, fitness centers and other public buildings for entertainment and sports purposes, which provide areas for playing ice hockey, short track competitions, figure skating. The design of the ice field was developed by the Belpromproject Institute and applied in a number of projects. Field constructions designed by the Belpromproject Institute are successfully operated in various cities of the Republic of Belarus and the Russian Federation. The basic design scheme for the ice field was first developed by the Belpromproject Institute in 1998, is constantly being improved and modified depending on the specific engineering and geological conditions of the construction site, space-planning decisions of the building, materials used by agreement with the customer. The basis of the design is a supporting reinforced concrete slab, arranged on an earth cushion or on piles. As a rule, heating pipelines are placed within the soil cushion, which protect the underlying soil from freezing. Layers of insulation and waterproofing are laid on the carrier plate, the slip layer is the most important component of the structure, ensuring the mobility of the seamless reinforced concrete technological plate of the ice field. Cold supply pipelines are located in the body of this plate, which ensure ice freezing on the surface of the plate. An anchor is also provided in the plate for fastening the sides of the ice field. The field is bordered by a system of drainage trays and channels for removing melt water and channels with cooling pipes connected to a refrigeration station.

Application of a roof from a sprayed polyurethane foam

Roofs from sprayed polyurethane foam are used in the construction of new and repair of existing roofs.

The most effective roofs are sprayed polyurethane foam from Elastopor H 1612 TU RB 190287814.001-2004 when repairing existing roofs in those cases when:

- overloads of existing coatings are unacceptable (Elastopor Н1612 1 sq.m. — 4.0 kg);

- while restoring the waterproofing carpet, a substantial increase in the heat transfer resistance of the entire coating is required.

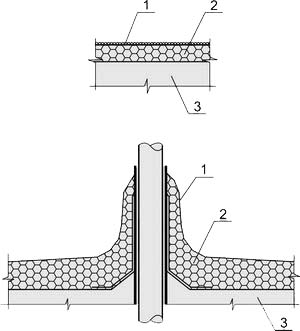

Elastopor H roof spray foam is a rigid polyurethane material. It is formed by mixing two initially liquid elements. As a result of mixing these two components, a reactive mixture is formed, which foams under the influence of heat. Applied in several layers of Elastopor H for all types of roofs, it provides reliable seamless waterproofing against precipitation in combination with thermal protection. The flow chart was developed on the basis of TU RB 190287814.001-2004 «Composition of polyurethane foam brand Elastopor N 1612. Technical conditions.»

- Protective layer of gravel on AUTOKRIN bituminous mastic or a layer protecting from exposure to ultraviolet rays (AUTOKRIN 177);

- Polyurethane foam sprayed roof Elastopor H 1612 TU RB 190287814.001-2004;

- The existing composition of the roof.

- Защитный слой гравия на битумной мастике АУТОКРИН или cлой защищающий от воздействия ультрафиолетовых лучей (АУТОКРИН 177);

- Пенополиуретановая напыляемая кровля Elastopor Н 1612 ТУ РБ 190287814.001-2004;

- Существующий состав кровли.

The use of a number of new design solutions in residential construction

Residential buildings at the intersection of Traktornaya — Zakharova streets, as well as along the Lagoisky tract street, are designed with load-bearing transverse brick walls. The step of the transverse walls is 7.2; 4.8; 6.0 m allows you to get large free spaces, providing in the dimensions between the walls of the free layout of living quarters. External walls — of cellular concrete blocks with a bulk density of 500 kg / m3 and a thickness of 400 mm are based on floor-to-floor slabs. Local sections of the external walls (end faces of slabs, brick pylons) are insulated by the «thermal fur coat» method. Facade decoration — plastering with polymer compounds followed by painting with weather-resistant facade paints. .

14-storey residential building on per. To the barracks in Minsk, in a constructive sense, it was solved in a prefabricated frame using structures manufactured in the formwork series 1.020-1. A distinctive feature is the absence of reinforced concrete consoles in the columns and a change in the support parts of the crossbars (there is no undercutting), which allows the production of crossbars of various spans in one form. The longitudinal arrangement of the crossbars in combination with the large span slabs (up to 9 m) and the original spatial and planning solutions made it possible to avoid protruding parts of the crossbars in residential premises.

An apartment building with built-in premises on Zhukovsky St. in Minsk, residential building No. 4 from a group of residential buildings on Prytytsky St. (from P. Glebka St. to residential development on Belsky St.) and a 12-storey 2-section building residential building with underground garage — parking on the street. Mayakovsky — Denisovskaya in Minsk are designed in a prefabricated modified frame using molds and accessories of the 1.020-1 series.

The characteristic features of this frame are:

- reducing the cross-sectional height of the crossbars from 450 to 260 mm, while the total thickness of the flooring and, accordingly, the height of the building as a whole, while maintaining a constant floor height in the light, are automatically reduced

- multi-hollow floor slabs have undercut in the end for hidden support on the crossbars of the crossbars, which allows to obtain a smooth ceiling surface;

- the absence of reinforced concrete consoles in multi-story columns allows you to vary the height of the floor without changing formwork forms;

- the fastening of the crossbars to the columns is hidden during welding with the subsequent monolithic joint, which ensures the perception of a fixed reference bending moment, thereby creating the effect of the continuity of the crossbars on the support.